Sleeve Anchor

Sleeve Anchors

In most cases, building a deck requires structural support. Exterior wall of the house can be used for this purpose. It is important that the header attached to the house is secured to the outside house as the deck will be attached to the header. Before commencing construction, it is highly recommended to follow local codes or to consult an engineer.

Application and material

Most sleeve anchors are used for light duty and heavy duty fastening, they are considered to be adaptable, using with concrete brick and block. Sleeve anchors are available in different sizes and in different head styles. For indoor and dry area zinc plated anchor is recommended while stainless steel is recommended for outdoor and wet environment.

Sleeve anchor installation steps

- Prior to proceeding be sure to have materials and required tools handy

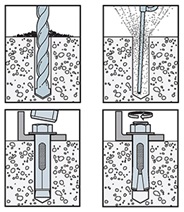

- For anchor installation, use a hammer drill to break up the base material. The rotating action keeps the whole clean for required tolerance.

- For proper installation, it is not recommended to use a straight rotation drill as it will create an improper hole. Hammer drill should be set to hammer and rotation mode.

- Proper installation requires to follow proper hole tolerance and it is recommended to use carbide tip bit that meets ANSI standards.

- Determine hole position

- Sleeve anchor installation requires to drill a hole of the same diameter as the anchor

- Hole should be minimum of 1/2 inch deeper than anchor penetration

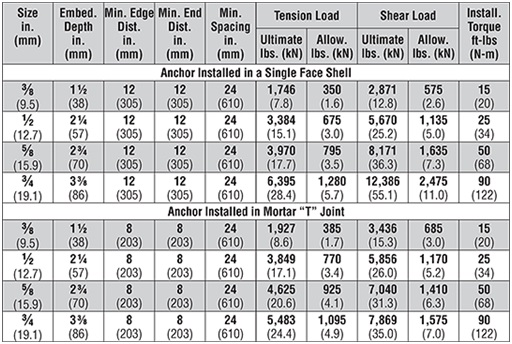

- Different size of anchor requires a minimum depth to ensure its holding values (follow chart). Surpassing deeper than minimum depths may increase holding values

| Sleeve Anchor Size | Minimum Depth |

| 1/4” | 1-1/8” |

| 5/16” | 1-7/16” |

| 3/8” | 1-1/2” |

| 1/2” | 2-1/4” |

| 5/8” | 2-3/4” |

| 3/4” | 3-3/8” |

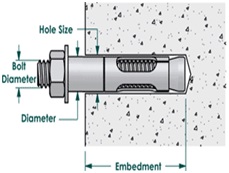

- See illustration below to determine how to measure length of the anchors

- Be sure to make the hole slightly larger than the diameter of the anchor

- Follow the chart displayed below showing the minimum diameter of the hole

| Sleeve Anchor Size | Minimum Hole Size |

| 1/4” | 5/16” |

| 5/16” | 3/8” |

| 3/8” | 7/16” |

| 1/2” | 9/16” |

| 5/8” | 3/4” |

| 3/4” | 5/8” |

- Depth Assurance

- For proper depth assurance two common methods are used. Most hammer drills have a depth gauge, which is designed to ensure proper hole depth. Set gauge as per chart above. If hammer drill has a depth gauge missing, wrapping a piece of tape around the bit at the proper depth will achieve same result, follow the above chart for taping around the bit. For each of the above methods, it is very important to set the bit in the most inward position in the chuck

- Hole Cleaning

- There are number of ways a drilled hole can be cleaned. For a minimum holding values and a proper installation of the anchor, it is critical that the hole is clean.

- Dust and debris can be cleaned using the same diameter wire brush by inserting in the hole and turning it in an up and down movement

- For safety measurement when using compressed air, be sure to wear eye protection as it will create dust and debris in the air

- Installation

- Sleeve anchors are pre-assembled with a nut and a washer, when dropping the anchor in the hole care must be taken not to damage threads (see illustration below)

- Tap the anchor with a hammer until the nut and washer are flushed with the surface

- Tighten nut with your hands and to complete the anchor expansion by using a wrench/screwdriver

- Do not over exceed the specified installation torque. Over torque can cause the anchor to fail its holding value and will cause the anchor to spin in the hole